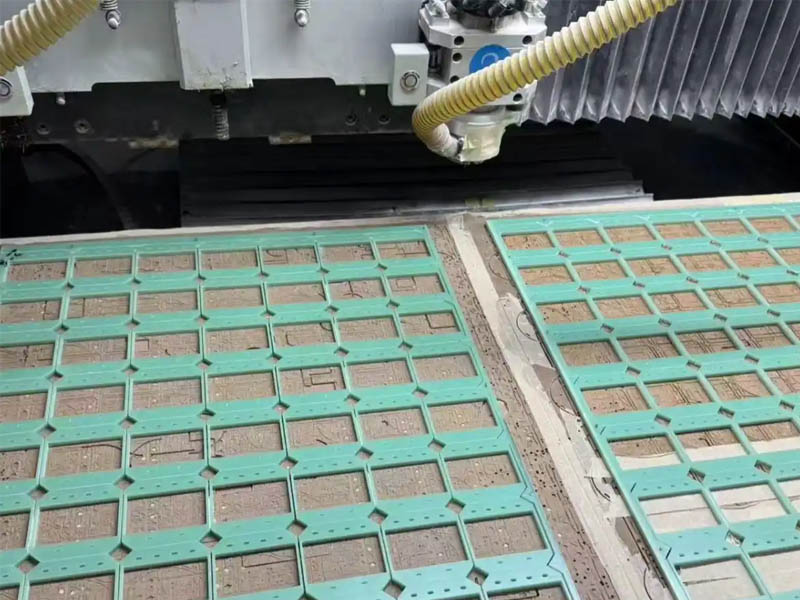

Речь идёт об использовании станков с ЧПУ для резки, формовки и сверления FR4 (огнестойкого стекловолоконного армированного эпоксидного композита) с целью изготовления прецизионных электронных изоляторов, опор для печатных плат и различных механических деталей, обладающих превосходной прочностью, электрическими свойствами и влагостойкостью.

Первый,

FR4

Это огнестойкий материал, состоящий из эпоксидной смолы и стекловолоконной ткани. Обозначение «FR» указывает на огнестойкость, а «4» — на класс огнестойкости. В основном используется в качестве подложки для печатных плат (PCB) и сырья для различных изоляционных компонентов. Обладает высокой механической прочностью, стабильными электрическими свойствами и хорошей термостойкостью, соответствуя стандарту огнестойкости UL94 V-0.

Так почему же для обработки стали FR4 используются станки с ЧПУ?

1. Высокая точность:

Материал FR4 склонен к расслоению, если процесс ламинирования выполнен с небольшой неравномерностью. В станках с ЧПУ используются компьютерные программы для управления режущими инструментами, а скорость и подача могут быть точно заданы с точностью до нескольких знаков после запятой, что позволяет контролировать погрешность обработки в пределах ±0,02 мм. Этого трудно добиться стабильно с помощью традиционных ручных методов или обычных станков.

2. Высокая эффективность: Станки с ЧПУ могут работать в автоматическом и непрерывном режиме, выполняя сверление, фрезерование и резку за один проход. Они также могут работать круглосуточно, что делает их особенно подходящими для массового производства. Например, при изготовлении изоляционных деталей для светодиодных абажуров сверление может быть дополнено фрезерованием для создания круга, что является быстрым и равномерным процессом.

3.

Универсальность:

Из него можно изготавливать различные сложные формы. FR4 часто используется для производства различных изоляционных прокладок и перегородок, которые могут иметь нерегулярные отверстия, изогнутые поверхности или тонкостенные конструкции. Многоосевая связь и возможности программирования станков с ЧПУ позволяют легко справляться с такими задачами, что является недостатком традиционных токарных и фрезерных станков.